Composite Spray Molding

Stiff; Low weight; Competitive cost.

Composite Spray Molding

G&G's composite Spray Molding (CSM) technology utilizes proprietary chemistry & proprietary delivery systems developed at G&G to enhance the composite molding process.

Characteristics of CSM parts:

• Incredibly stiff

• Low weight

• Have best-in-class dimensional stability

• Improved surface aesthetics allowing for broader product applications

• Improved mold filling that improves design flexibility with transitional surfaces

• Reduced polyurethane usage

Why Composite Spray Molding?

CSM has proven to be highly effective over the years. Its key benefits include high strength-to-stiffness weight ratio, complete design flexibility, and a competitive cost. By adjusting CSM glass content and core thicknesses, a wide range of parts can be produced; CSM is extremely versatile. While a sunshade represents a thin, lightweight, full trimmed part application, CSM is also used in thicker, load-bearing Load floor panels.

CSM can be molded into complex shapes, with varying thicknesses for unique part applications. The parts can be covered with a wide range of textile materials, and offer tremendous weight savings over traditional materials.

The Process

The CSM process utilizes proprietary chemistry & delivery systems that are unique to G&G Industries.

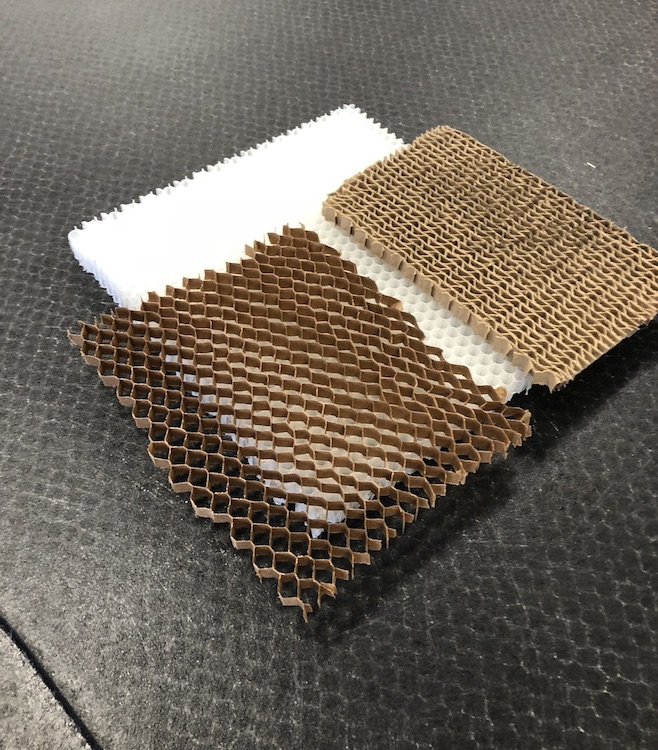

CSM is manufactured using an automated spray application over a composite core of paper honeycomb and fiberglass.

CSM Product Applications

• Load Floors

• Sunshades

• Interior Panels

• Seat Back Closeout Panels

• Structural Panels

• Package Shelves

• Spare Tire Cover

• Tail Gate Inner

• Tonneau Covers

• Cargo Gap Hiders

• Skid Plates

• Battery Trays

CSM Load Floors

• Load floors have optimized glass and polyurethane content to meet physical requirements and cost objectives.

• Load Floors are thermoset and demonstrate exceptional dimensional stability, resistance to heat sag while maintaining a very high flexural modulus.

CSM parts:

• Are customized for your application

• Adjusted for thickness & glass content

• Have customized honeycomb/spacer technologies

• Have optimized mass and flexural strength

• Are lightweight with very high flexural modulus

• Have excellent heat sag properties

• Have thermoset-excellent dimensional stability

G&G’s production system is capable of high volume production runs, with less than average maintenance as compared to other delivery systems, making it ideal for high-volume production.

With a high strength-to-weight ratio, complete design flexibility, and a competitive cost, CSM is the ideal solution for almost any interior trim component.